Welcome to our Insight blog where you will find stories and announcements that pertain to the industries Pyrotek serves, from aluminium to zinc galvanizing to glass to acoustics to battery materials and more.

CASE STUDY: Steel Plant Reduces Energy Loss by Choosing ISOMAG Structural Insulation

by David Cole | 1 November 2022

Pyrotek delivered an insulating solution that enabled a customer in Eastern Europe to reduce energy consumption related to their steel ladle by EUR€250,000 per year and delivered a return on their investment in less than three months.

Pyrotek Receives Contractor Award from Constellium Muscle Shoals

by David Cole | 7 June 2022

Constellium Muscle Shoals' aluminium manufacturing operation in Muscle Shoals, Alabama, USA, presented Pyrotek with a "Contractor of the Year Award," following molten metal furnace refractory relining and maintenance work. Since 2015, Pyrotek's refractory services team has been providing refractory linings for furnaces, crucibles, and troughs for Constellium Muscle Shoals.

Ceramite Dual-Cast Crucibles Offer Maximum Life

by David Cole | 1 June 2022

At 2.5 tonnes capacity for molten metal, a Pyrotek Ceramite® Dual-Cast Crucible transfer ladle is the largest in use today at any foundry in Western Europe. It’s currently performing successfully for premium automotive foundry in Germany.

RFM® Ladles Save Foundries from Frequent Changes, Downtime, Metal Sticking

by David Cole | 4 June 2020

Pyrotek reinforced fiberglass material (RFM®) ladles are helping foundries around the world cut way down on inclusions flowing into their finished castings, and reducing the frequency of ladle-change stoppages caused by metal sticking and wear.

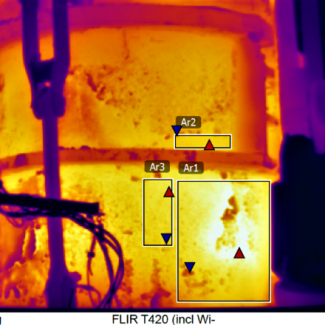

Increasing Ladle Efficiency and Service Life Through Proper Preheating Technology

by David Cole | 4 May 2020

“It’s crucial that our customers get the highest performance from their transfer ladles and have the safest, most efficient process of preheating them,” says Mike Tomassi, Chief Engineer at Pyrotek’s Cortland, New York, USA, facility. “Our transfer ladle preheat systems help operators properly heat their vessels so they can spend more time operating and less time in maintenance.”