Welcome to our Insight blog where you will find stories and announcements that pertain to the industries Pyrotek serves, from aluminium to zinc galvanizing to glass to acoustics to battery materials and more.

ConMet Mexico Turns to Pyrotek Graphite Shafts and Rotors

by David Cole | 17 February 2025

ConMet’s facility in Monterrey, Mexico, which makes aluminum castings for the heavy trucks industry, has found that switching to Pyrotek’s graphite shafts and rotors used in degassing processes has reduced maintenance downtime, allowed for more efficient stocking of supplies, and ensured customer orders are fulfilled on-time.

CONTAINER GLASS: How Low-Porosity Refractory Stirrers Boosted Plant Efficiency

by David Cole and Paul Chevolleau | 28 October 2024

The right refractory material for stirrers in a colorant forehearth can eliminate streaky glass and increase plant efficiency and safety.

Pyrotek Installs Another Integrated Melting System (IMS) at Customer Site

by David Cole | 14 August 2023

The IMS consists of equipment specifically engineered to process machining chips, converting it efficiently back to usable metal.

Major Foundry in Spain Installs Pyrotek Degassing Units to Optimize Metal Treatment

by David Cole and Saul Gracia Villacampa | 31 January 2023

MAPSA Has Chosen Pyrotek for Advanced Degassing Technology Expansion.

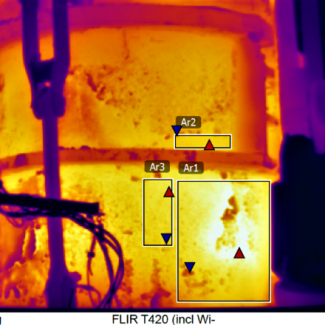

CASE STUDY: Steel Plant Reduces Energy Loss by Choosing ISOMAG Structural Insulation

by David Cole | 1 November 2022

Pyrotek delivered an insulating solution that enabled a customer in Eastern Europe to reduce energy consumption related to their steel ladle by EUR€250,000 per year and delivered a return on their investment in less than three months.

Pyrotek Receives Contractor Award from Constellium Muscle Shoals

by David Cole | 7 June 2022

Constellium Muscle Shoals' aluminium manufacturing operation in Muscle Shoals, Alabama, USA, presented Pyrotek with a "Contractor of the Year Award," following molten metal furnace refractory relining and maintenance work. Since 2015, Pyrotek's refractory services team has been providing refractory linings for furnaces, crucibles, and troughs for Constellium Muscle Shoals.

Pyrotek Delivers Experienced Furnace Cleaning Services

by David Cole | 8 February 2022

Pyrotek safely cleans furnaces and associated launders, removing dross, corundum, and oxides by utilizing specialized tools, fluxes, and inert gas when necessary.

Pyrotek Transfer Line is Ideal Customized Solution for Foundry in Spain – And Right on Time in Urgent Situation During Holiday Production Shutdown

by David Cole | 24 August 2021

Pyrotek delivered and installed a 19.5-meter (64-foot) transfer line (launder) with infrared heating lids at CIE C. Vilanova, a high-pressure die casting plant in Barcelona, Spain. A previously installed transfer line provided by another vendor was leading to freezing aluminium, metal overflows, and unsafe conditions.

Automotive Assembly Plant in Mexico Selects Pyrotek’s Rigid Glasweve® Filters as Standard Filter for Casting Cylinder Heads

by Andrew Carlson and David Cole | 22 April 2021

The aluminium foundry at a major automotive operation in Mexico is now using Rigid Glasweve (RGW) filters as part of its cylinder head casting process, finding after a large-scale trial that RGW reduced scrap compared with the use of ceramic foam filters (CFF).

CASE STUDY: Cable Casting Operation Turns to Pyrotek Experts For Advanced Molten Copper Transfer Solution

by David Cole | 12 February 2021

As a result of this longer lasting transfer launder, the copper caster is now in a position where maintenance has decreased and metal cleanliness has improved, delivering measurable savings.

CASE STUDY: Aluminium Plant Improves Potroom Crucible Lining Service Life by Five Times

by David Cole | 27 January 2021

A large aluminium producing plant in Turkey has found that choosing a Ceramite® refractory lining for its crucibles increased the service life of the linings by five times - and resulted in easier and reduced maintenance, along with increased efficiency and more production time.

Rigid Glasweve Replaces CFF as a Production Filter at Major Automotive Caster in Spain

by David Cole | 21 January 2021

Rigid Glasweve® (RGW) filters have been chosen as the preferred filter for the casting process, in a sand-casting application, at a major automotive parts caster in Spain, Saint Jean Industries – Valladolid (SJI).

French Foundry Turns to Pyrotek for Critical Furnace Project Amid Health Crisis

by David Cole | 23 October 2020

When a major foundry in France, a supplier of cast parts to the country’s automotive manufacturers, needed two dosing furnaces relined, a new control system for the furnaces, and an advanced electrical cabinet, and they needed it all during a pandemic when worker health and safety was on everyone’s mind—they turned to Pyrotek.

RFM® Ladles Save Foundries from Frequent Changes, Downtime, Metal Sticking

by David Cole | 4 June 2020

Pyrotek reinforced fiberglass material (RFM®) ladles are helping foundries around the world cut way down on inclusions flowing into their finished castings, and reducing the frequency of ladle-change stoppages caused by metal sticking and wear.

Demand More from Your Degassing Consumables with RFM® Sleeved Degassing Shafts

by David Cole | 26 May 2020

Maximizing the lifetime of graphite degassing consumables is critical to decreasing downtime and improving process efficiencies.